Content

Inside Britain’s bio lab: an interview on biotechnology in construction with Martyn Dade-Robertson

With rumours of mushroom homes and fungi floors, biotechnology in construction has some excitement brewing around it. But what does biotech in the built environment really look like? And how can construction get involved? BE-ST's Sam Patterson & Newcastle University’s Martyn Dade-Robertson sit down to explore what’s possible.

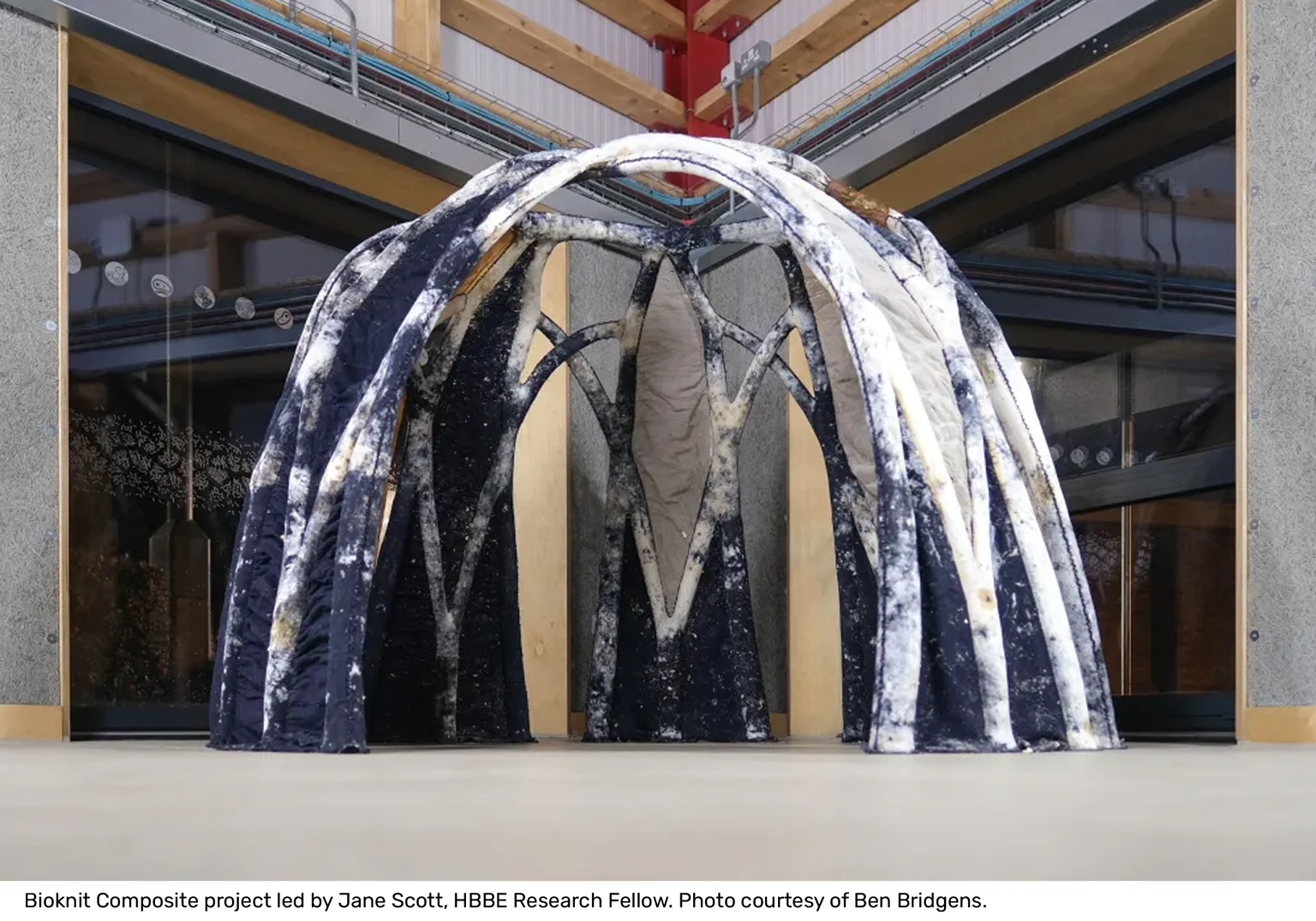

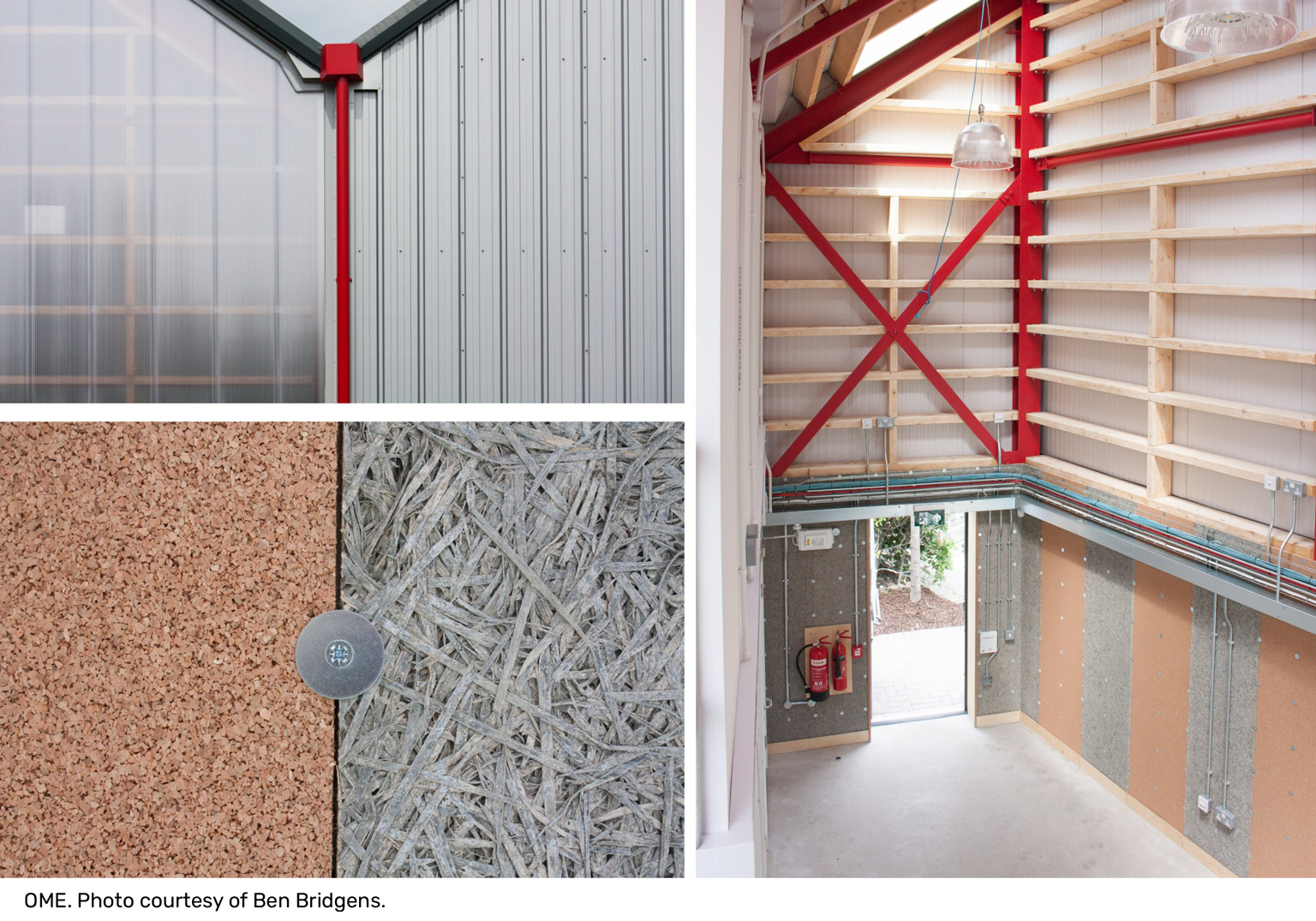

In one corner of Newcastle University stands a unit called the OME. At first this building may appear unassuming but inside is part of the UK’s first Bio Lab for construction: a new living laboratory testing bio-organisms as building materials. From molecular glue to circular concrete, here academics put early-stage technologies into practice at a building scale in the hopes that they could apply to our built spaces sometime in the future.

One of the minds behind this living lab is Martyn Dade-Robertson, a researcher at Newcastle University and Co-Director of the Hub for Biotechnology in the Built Environment (HBBE).

Martyn will be presenting at our BE-Bio Tech event on 14 March at BE-ST Campus. Ahead of the event, our Sustainability Associate Impact Manager Sam Patterson sat down with Martyn to explore the exciting potential of biotechnology for construction and demystify what it means.

According to Martyn, the biological possibilities are limitless – but first industry and academics must put heads together over the possibilities, challenges and solutions.

Sam: What does biotechnology in construction mean?

Martyn: It's a spectrum, right?

In construction we often make use of the materials that nature provides, usually after the organism that created them has died, and then we chop them up and we make them into materials. We also tend to treat them to make them ready for use.

The biotech approach that we would take is to try and use the capabilities of the organism while it is still actually alive to shape its growth or the formation of materials as part of a living fabrication process.

The idea that we’re trying to explore is a building in which some of your materials may be alive, and if the building material is alive, that opens up the possibility of it being, for example, capable of self-healing, or adapting to the changes in its environment, maybe even reproducing in some way.

Sam: How is biotechnology is currently being used in the construction? Is there anything that you see has been the early trailblazer that’s readying to go to market?

Martyn: There are products on the market already. There are products that use living construction type approaches similar to what we're using. One example is the use of mycelium. This biotechnology leverages the root network of fungus and it is being held up as a kind of wonder material. It grows very quickly, it can grow on waste, and will act as a binder to whatever aggregate it grows on.

What you get at the end of it is a fairly tough material. It's an excellent insulator, and it has the added benefit of being water resistant.

I believe there are several companies that have been set up to try to make it into an insulation material and bring it to market.

One of the leaders in the mycelium space is a company called Ecovative, who make foam and packaging products out of it, and they have a few different spin-out companies.

Other than getting it through building regulations, I see no reason why it’s not an eminently scalable material.

Sam: How do you see biotechnology companies being able to support construction? What would that collaboration look like?

Martyn: From our perspective, what we lack at the moment is a good understanding of the specific challenges. There's a bit of a bridge to be built at the moment.

We started exploring building insulation after we were at an event and every second person came along and said, can you do building insulation? Because this remains one of the big unsolved challenges. We need more of it than ever.

And, when it comes to the built environment’s biggest challenges, we’re trying to work out if there are any biological solutions. Is there an enzyme that will break down waste products to make something which we can use? How can we measure the amount of energy or CO2 emissions from a waste product? There are limitless biological possibilities. But at the moment we have to use our intuition to work out where the main challenges are likely to be.

I think partly because the construction sector is waiting for us to produce the ‘wonder thing’ to solve all the problems, and we're waiting for the construction to say these are our absolute problems. Up to this moment and since creating the HBBE, we've never really managed to get that deep dialogue and without it, there's going to remain a gap there.

As we've heard from Martyn and Sam, biotechnology has the potential to make an impact on the construction industry someday, from creating self-healing and adaptable living buildings to developing new and sustainable building materials. However, collaboration between biotech and construction companies is crucial to unlocking this potential and bringing these innovations to market.

If you're interested in exploring these possibilities further, we invite you to get in touch.

Prof. Martyn Dade-Robertson

Professor of Emerging Technology

University of Newscastle

Sam Patterson

Associate impact manager

BE-ST