Content

Creating a retrofit digital twin - Elemental Power in ALCHEMAI

Elemental Power specialises in developing digital twins for local energy systems, a technology that combines technical and economic modelling to simulate and optimise energy usage in non-domestic settings.

As part of the ALCHEMAI project, Simon Le Blond shares how Elemental Power is collaborating with other partners like Holosphere, which focuses on immersive visualisations, to build a digital twin that presents actionable data to users in engaging and accessible ways.

The core objective is to help stakeholders, such as local authorities, plan and execute retrofitting projects for sustainable energy while balancing factors like operational carbon emissions, costs, and the feasibility of implementation.

What are digital twins?

Digital twins, as applied in ALCHEMAI, are highly sophisticated simulations that analyse current energy systems and explore future upgrades.

They evaluate multiple scenarios to determine the best path forward, taking into account operational emissions, capital expenditure, operational costs, and payback timelines. Simon says, “Digital twins are an essential tool, helping to quantify what's required and evaluate the benefits of different retrofitting decisions in terms of costs and carbon savings.”

“Every decision to invest is based on some sort of business model. But the digital twin offers a very granular and insightful model that gets the data and captures the detail that's required to make those informed decisions.”

Integration with Immersive Graphics

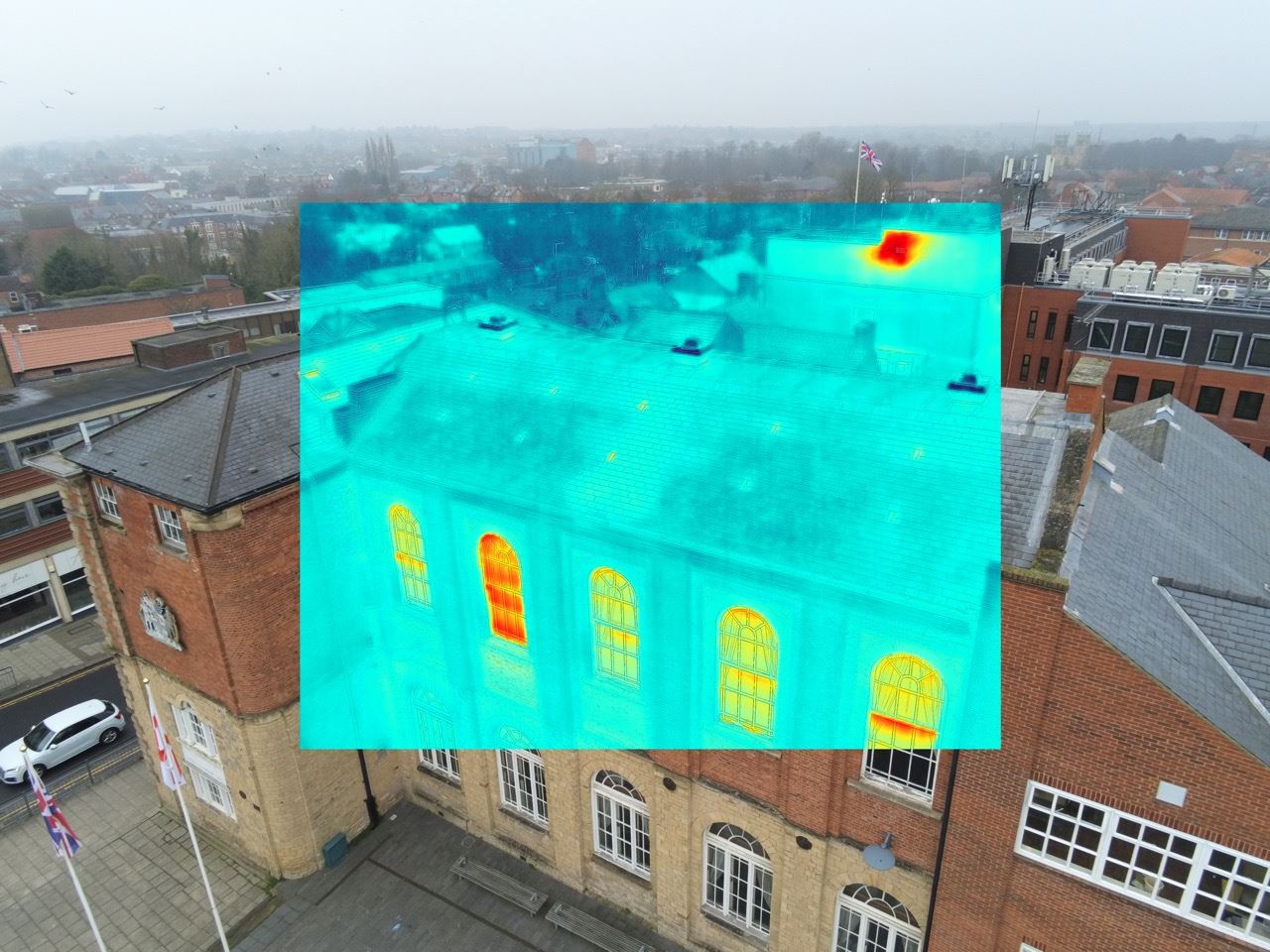

Elemental Power ensures their technical models are paired with Holosphere’s visualisations, allowing stakeholders – like planning authorities or less technically proficient users – to understand energy impacts intuitively. Part of their work, Simon says, is “calculating the right numbers so that they can be communicated back to user in a visually engaging way.”

For the digital twins to be a success, Elemental Power is sourcing real data gathered from sensors from another ALCHEMAI partner, Atamate. The ability to simulate dynamic conditions, such as fluctuations in solar generation due to weather, makes their models highly accurate and actionable. Simon says, “The data that we get back from the pilot sites is enriching the existing digital twin.”

Artificial intelligence in the technology

Elemental Power’s tool uses a deterministic calculative model for the central simulation which ensures consistent and repeatable results for any simulated scenario with the same input parameters. The use of AI is complementary to this by providing an efficient optimization wrapper to the simulation (rather than having to simulation every possible scenario). Simon says, “Our models aim to provide energy managers with actionable insights into where the ‘low-hanging fruit’ of retrofitting is, enabling them to prioritise investments wisely,” especially with costs.

Simon also sees AI as being useful as an outer wrapper to assist users with their energy literacy, and standardising input data, allowing people to easily upload different supplier documents or energy bills into the model.

ALCHEMAI is allowing safe learning

Simon shares one of the benefits of being part of the ALCHEMAI project: “There's quite a wide range of building types for us to cut our teeth into, which is quite a good situation to have because it means we can develop that capability in a safe environment in the context of an innovation project, rather than a commercial job.”

Future for digital twins in retrofitting and sustainability

Digital twins empower asset owners by identifying quick wins and optimising budgets for maximum impact when planning a retrofit. The learnings drawn from the ALCHEMAI project extend to a variety of building types, including historic buildings, commercial spaces, and high-energy-use facilities like leisure centres.

Elemental Power sees digital twins as indispensable, blending cost-effectiveness, carbon efficiency, and operational control.