UK Cross Laminated Timber (CLT) & Glued Laminated Timber (Glulam)

What are CLT and Glulam?

The two most prevalent mass timber products in the UK market, CLT and Glulam, are both manufactured using similar processes, but to serve different purposes.

CLT panels are wood layers glued together at a perpendicular angle, delivering a high-performance, wide and flat panel used for walls, floors, and roofs. Glulam beams are wood layers glued together parallel, creating a long, narrow but high-strength product for beams, columns, and trusses.

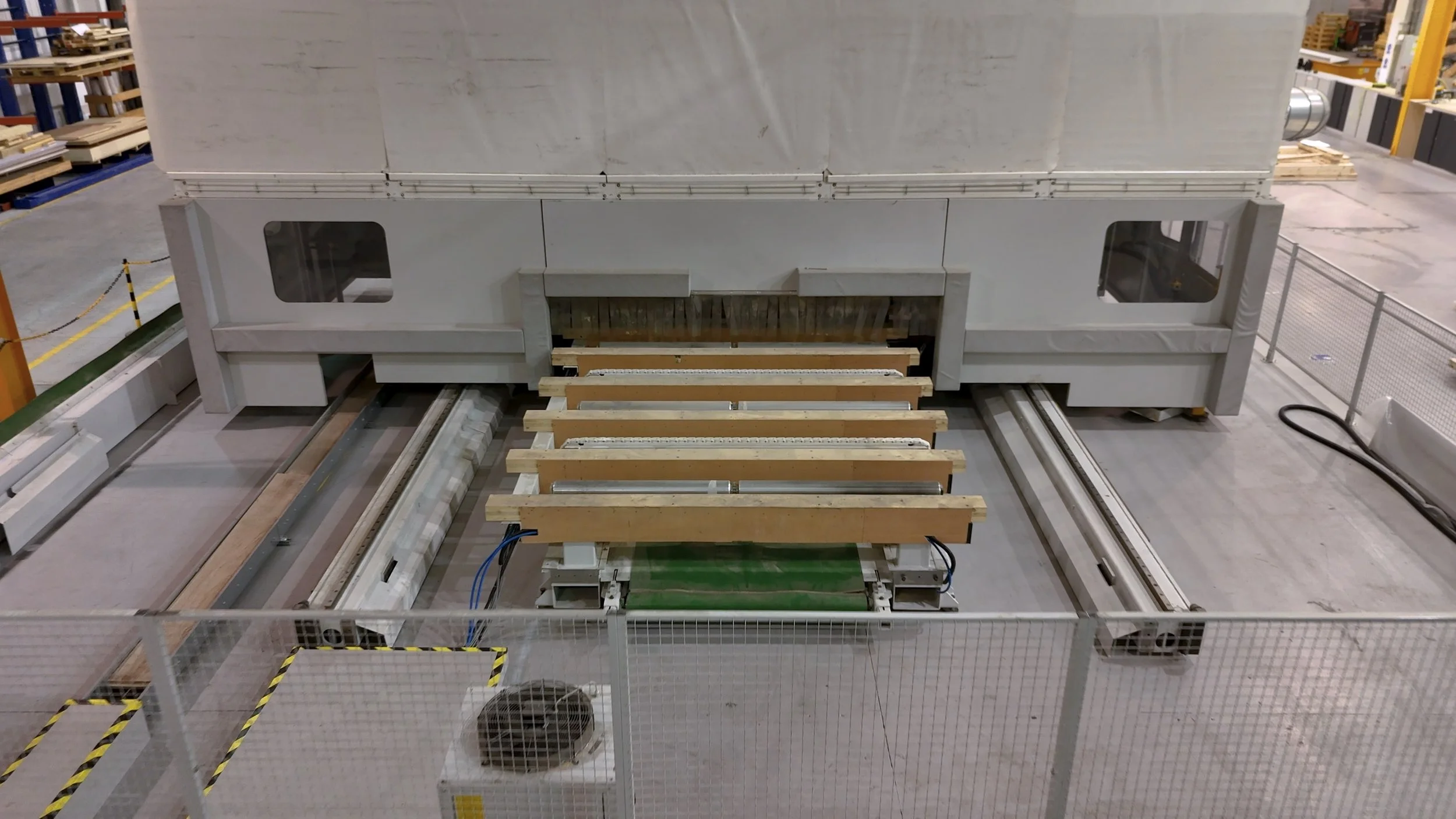

When correctly grown, harvested, and processed, timber in the UK can meet the structural grading requirements for structural load-bearing construction. The Mass Timber Centre of Excellence has the capacity to manufacture both with precision for a variety of purposes.

Both offer a high-strength alternative to steel. Researchers at Edinburgh Napier University determined that timber grown in Scotland that is strength graded to C16 demonstrates enhanced properties compared to imported C16, specifically in bending strength and timber density, resulting in the strength class C16+

Why choose mass timber for construction?

The main benefit of UK-grown timber is that it has the potential to create higher quality, faster, more sustainable construction at scale. The main drivers for UK grown mass timber are speed, performance & strength, sustainability, financial incentives and occupant experience.

Performance: Fully compliant with structural safety standards.

Versatility: Ideal for load-bearing beams and columns in low-to-medium rise developments.

Speed: A specific UK housing project utilising a volumetric timber system was able to demonstrate a 50% faster build time compared to traditional construction methods.

Cost Efficiency: Imported timber carries a premium. Homegrown C16 graded timber is currently £50/m³ cheaper than imported C24 alternatives. CLT made from C16 is suitable for many projects. We help you leverage these savings without compromising on structural integrity.

Supply Chain Security: The UK currently imports 81% of its wood raw materials. By specifying UK CLT, you insulate your project from global supply chain volatility and support the domestic forestry sector.

Occupant experience: Occupants in surveyed UK mass timber buildings consistently report feeling more relaxed and comfortable.

Net Carbon sink: Homegrown volumetric units achieve a net carbon sink of -142 kgCO₂/m², compared to +612 kgCO₂/m² for brick and block.

Case study: CLT in Practice

The time savings are substantial. Looking at the retrofit of Scotland’s National Retrofit Centre, project Manager Gavin Johnston attributes manufacturing offsite with mass timber as the reason that allowed us to complete this complex programme within such an ambitious timeframe.

Built by Ecosystems Technologies and Clark Contracts, the project used an offsite manufactured CLT panelised system for walls, made from homegrown sustainably sourced timber, to create the impactful external façade. The project utilised the machinery and equipment in the Mass Timber Centre of Excellence as well as the training rigs as a living lab teaching tool when the panels were being constructed and installed at each stage.

The MMC approach has allowed internal and external programmes of work to happen simultaneously, without interrupting each other. Gavin said: “We've created two working sites internally and externally, which are independent of each other. This has allowed us to deal with the tight timescales on this programme because we've been able to progress internal works both in terms of strip out and fit out, whilst working in the factory on the external facade system.”

This approach meant that we completed all the CLT panels over 5 lift sessions, which represented the full façade across three elevations of the building.

Forward planning is crucial to making this unique approach to retrofit successful, but taking on a manufacture-driven approach has led to delivering a high-quality product while also making the build more efficient.

Explore the benefits of timber

We provide the expertise, research, and manufacturing capabilities to make UK Cross Laminated Timber (CLT) and Glulam the sustainable construction material of first choice.

Through the Mass Timber Centre of Excellence and Transforming Timber, we have spent the last 5 years disproving myths and advancing research. This work verified that UK-grown Sitka Spruce meets Eurocode 5 structural requirements, proving it is perfectly suited for high-performance CLT and Glulam applications.

Our CLT manufacturing, consultancy and research centre is shifting the market from imported reliance to a circular, homegrown economy.

Manufacturing capabilities at BE-ST

We are not just researching, we also have CLT manufacturing capabilities. With a proven track record of delivering projects with from UK grown timber, the BE-ST Mass Timber Centre of Excellence is rapidly expanding UK production capacity.

Current Trajectory: scaling from 2,000 m³ to 8,000 m³ annually per shift by 2026.

Future Potential: Fully automated capacity of 12,000 m³ - enough to build 1,000 NearHome units per year.

Would you like to integrate timber in your projects or build using offsite construction methods?